OPTIMIZATION CUTTING MACHINE PERFORMANCE IN CAREERS

Stone Assistance has been interested for several years in improving careers sawing techniques with cutting machinery chains.

Rigorous scientific approach to the problem has been developed to increase the profitability of this phase of sawing and make it more competitive.

Our approach is as follows:

Characterization of the mechanical properties of the stone

Study theoretical performance tools by laboratory tests

Choosing a suitable configuration

Performance monitoring on site using onboard instrumentation

Calculation of production costs

LABORATORY TESTS

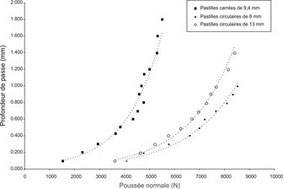

Laboratory tests are designed to assess the cutting performance configurations based on tests carried out on all media individually. These tests determine the distribution of forces on the configuration and locate the most stressed and least effective tools. This information helps to define the main causes of poorer functioning of certain configurations.

Tools of the same configuration tested individually.

Distribution of forces on a cutting configuration.

Comparing the response of three different configurations for cutting tests.

Laboratory cutting tests.

The performance of different configurations can be compared with each other to determine which ones will be most effective and thus guide operators to select the type of tools best suited to the application. Stone Assistance take those results in considereation to suggest design changes that will improve performance.

Instrumentation on site

Stone Assistance also works on machines to instrument them and monitor their performance in order to validate the developed concepts. The instrumentation notably allows operators to be more sensitive to certain phenomena occurring during operations.

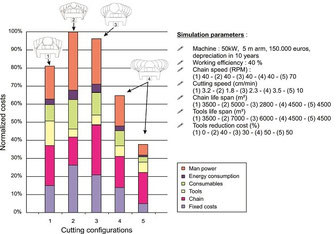

EVALUATION OF PRODUCTION COSTS

Stone Assistance has also developed a program that calculates the real cost of sawing with chains cutting machinery. The program allows to integrate the results of laboratory tests, technological parameters of machines and major costs to provide engineers with tools objective selection criteria.

For more information on the developed method, we recommend the following publications:

- F. Dagrain, P. Marchandise, P. Brux, S. Desmette. Etude et développement de nouvelles configurations de découpage pour les chaines de haveuses. Pierre Actual, Volume 885, Juillet-août 2010, pp. 54-57.

- F. Dagrain. Etude des mécanismes de coupe dans le Petit Granit de Soignies en vue de l’amélioration des performances des haveuses. Pierre Actual, Volume 886, septembre 2010, pp. 51-58.

- F. Dagrain, P. Marchandise, S. Desmette. Design d’une nouvelle configuration de découpage pour le havage en carrière en vue de l’optimisation du fonctionnement des machines. Pierre Actual, Volume 887, octobre 2010, pp. 52-59.

- F. Dagrain, P. Marchandise, P. Brux. Instrumentation de haveuses en vue du suivi de leurs performances sur site. Pierre Actual, Volume 905, Mai 2012, pp 56-60.

Contact us, and we will deliver you a copy !

Stone Assistance SRL

Dr Ir Fabrice Dagrain

+32 (0)494 89 32 51

BE 0546.726.939

Siège social

Clos des Botteresses 4

B-4317 Viemme

Belgique

Siège d'exploitation - Labo

Rue du Joncquois 53

B-7000 Mons

Belgique